o ring channel design|ERIKS : Manila Below, four standard application groove design guidance tables are presented along with dimensional reference drawings. The first table is for industrial face or . Tingnan ang higit pa Today’s top 97,000+ Game Tester jobs in India. Leverage your professional network, and get hired. New Game Tester jobs added daily.

o ring channel design,Global O-Ring and Seal has developed o-ring groove design and gland dimension guidelines. These are intended for use in basic design consideration and to understand the core principles involved in o-ring gland/groove design. Numerous factors go into the appropriate design of a . Tingnan ang higit pa

The o-ring cross-section in your design will determine all your subsequent dimensions and specifications. Standard o-rings are available in various cross-sections and inside dimensions (ID). For example, an o-ring with an ID of 5 ¼ can be purchased in four . Tingnan ang higit pa

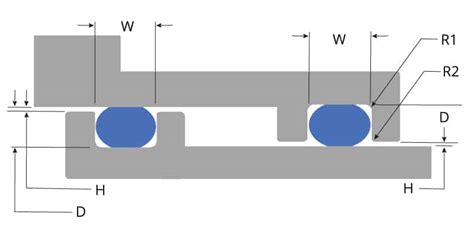

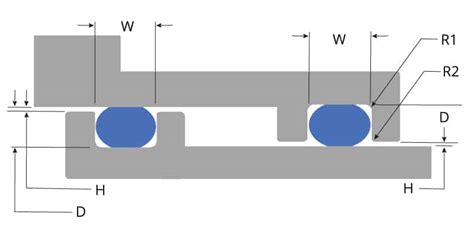

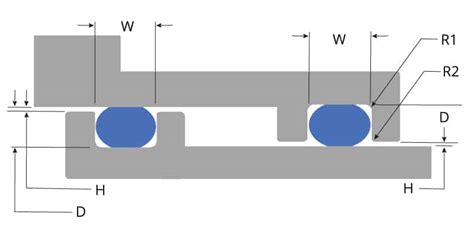

Below, four standard application groove design guidance tables are presented along with dimensional reference drawings. The first table is for industrial face or . Tingnan ang higit paThe design tables displayed above were created using best practices, including Compression Ratio, O-Ring Extrusion, Concentricity and Diametric Gap, and Backup . Tingnan ang higit pa12. O-ring Gland Design. The following pages contain basic O-ring gland design information. Please contact the local ERIKS repre-sentative if an application does not .O-ring groove design guides offer default dimensional guidance on the most basic o-ring groove design applications. The best o-rings are useless without the right groove design .

The o-ring groove (O-ring gland) is the most important design feature for producing efficient O-rings. They come in different shapes and sizes depending upon the .Designing the parts of an application where o-rings will be applied is broadly termed “o-ring groove design”. In order to seal properly, the o-ring has to deform in the application by being compressed and stretched in any .

O-ring groove design is a key consideration in the o-ring selection process. Browse design considerations and recommendations for static face seals, metric o-rings, static dovetail .

O-rings are reliable and affordable, which is why they’re a popular solution. But you need a good groove design for the O-ring to do its job properly. This guide will walk you through our best tips for designing O-ring grooves.Our o-ring groove design guides list default o-ring groove dimensions for the most basic applications and are intended to be used with the following o-ring groove design considerations to engineer an o-ring gland to .Our o-ring groove design guides list default o-ring groove dimensions for the most basic applications and are intended to be used with the following o-ring groove design .

O-ring design guides for engineers are helpful resources to find the exact o-ring material specifications needed. O-ring design guides, sizing charts, chemical compatibility .Conversely, when designing systems which seal equipment from external pressure, the groove's inside diameter (ID) is primary. This design technique minimizes movement of the O-ring in the groove due to .

O-ring groove design is an important aspect of creating effective and reliable seals. It involves careful consideration of gland depth, surface finish, clearance, compression and more. Proper groove design provides optimal sealing performance, extends the lifespan of the O-ring, maintains pressure retention, reduces maintenance costs, and .The groove must provide sufficient space so that the O-ring does not swell out. This would increase the compression and thus increase friction. 4. Stretching Piston seal example: O-rings must be stretched during assembly in order to snap into the installation space. It is important that the maximum elongation of the O-ring is not exceeded.O-Ring Groove Design. O-Ring Groove design plays an important part in how an o-ring seals. Learn More > Contact. Call Us: 716-759-2222; Send us a message; Call Us. 716-759-2222. Employment; Home; . O-Ring Size AS568B: W Cross Section. L: Squeeze: G Groove Width: R: Nominal: Actual: Gland Depth: Actual % Liquids: Vacuum and Gases: .

Note 1: Groove Depth = machined channel Gland Depth = Groove Depth + Clearance. Note 2: The following sizes are not normally recommended for dynamic service, although special applications may permit their use: Note 3: Clearance shown are based on 70 durometer materials. The clearances must be held to an absolute minimum consistent .

Use our interactive O-ring calculator to help select the optimum size O-ring to use, in accordance with the principles within ISO 3601. With a user friendly interface, and no login required, it will give recommended housing dimensions and allow you to assess the impact on sealing parameters where hardware sizes are adjusted to suit your .Imperial PTFE O’ring Groove Design. Due to PTFE’s (Teflon®) highly limited deflection ability, the following table has suggested groove dimensions for open face seal (flange) type grooves using imperial PTFE o’rings. PTFE o’rings in radially loaded closed grooves are generally not recommended, however if this is unavoidable, PTFE o .o ring channel design The Parker O-Ring Handbook is a hardcover manual with 11 chapters detailing O-ring design. The chapters range from tutorial to purely technical in nature.

Dovetail grooves are used to hold the O-ring in-place on a face seal groove during during assembly and maintenance of equipment. Skip to content. Call Now: 716-759-2222. Search. MENU . O-Ring Groove Design. O-Ring Groove design plays an important part in how an o-ring seals. Learn More > Contact. Call Us: 716-759-2222; Send us a message; Call .

Click here for more information on face seal groove design. Note the O-Ring inside diameter for the next step. Calculate the Seal Stretch. Using Equation 1, calculate the installed seal stretch. If the installed seal stretch is greater than about 3%, you may have to select the next larger O-Ring or require a custom O-Ring for your application.O-ring sealing, careful consideration must be given to the size of the O-ring in relation to the size of the glandular space into which the O-ring is being installed. The actual calculation for the cross section needed in an O-ring varies depending on whether it will be used in a dynamic or static application. In a dynamic situation,

ERIKS Static Male and Female O-ring Seal Design . Design Chart 4-2 and its accompanying Design Table 4-2 (available by clicking on the chart image at the bottom of the page) give one set of dimensions for static O-ring .standard P.A.I. O-ring sire. Dual turn rings conform to MS 28782 and match the dash numbers of an AN 6227 series of O-rings. MS 28783 back-up rings match the dash numbers an AN 6230 O-rings. Good practice is to use a back-up ring on either side of the O-ring, even though the pressure on the ring may be from one side only. The only time .12. O-ring Gland Design The following pages contain basic O-ring gland design information. Please contact the local ERIKS repre-sentative if an application does not clearly fall into these design parameters. Static Applications There are five types of static O-ring applications: • Flange seal • Radial seal • Dovetail seal • Boss seal .leak check procedure to preseat the O-rings and monitor for pressure blow-by (see figure 6). A fixture chamber O-ring ensured proper sealing between fixture halves and prevented any atmospheric leakage during testing. The pri- mary and secondary O-rings had inner diameters of 6.052 inch and 8.022 inch, respectively.This o-ring gland design guide is intended for use in specifying o-ring and gland dimensions for static applications with pressures up to 1500 PSI. For dynamic applications and for pressure greater than 1500 PSI, please contact Dichtomatik North America. The guidelines are for the nominal condition. The minimum and maximum stack-up .

Without sufficient O-ring seal protection or proper O-ring gland design, the O-ring seal can be irreversibly damaged. Harder O-ring materials and Backup Rings typically produce a more extrusion resistant system. Depending on the pressure levels, smaller O-ring clearance levels may be recommended. What is Channel Design? Channel Design is a design or plan prepared for the distribution and movement of goods and services from the manufacturer to the customer. Thus, Channel Design Decisions refer to the strategic choices and actions taken by a company to create an effective distribution and communication network for its .

o ring channel design|ERIKS

PH0 · O

PH1 · Engineer Technical Reference Guide for O

PH2 · ERIKS